祝贺王东涛老师论文 Microstructural refinement and α-dispersoid evolution in direct-chill cast Al-Mg-Si-Fe alloy被Advanced Engineering Materials接收。

题目:

Microstructural refinement and α-dispersoid evolution in direct-chill cast Al-Mg-Si-Fe alloy

作者:

Dongtao Wang, Haitao Zhang*, Hiromi Nagaumi, Xueke Li and Jianzhong Cui

摘要:

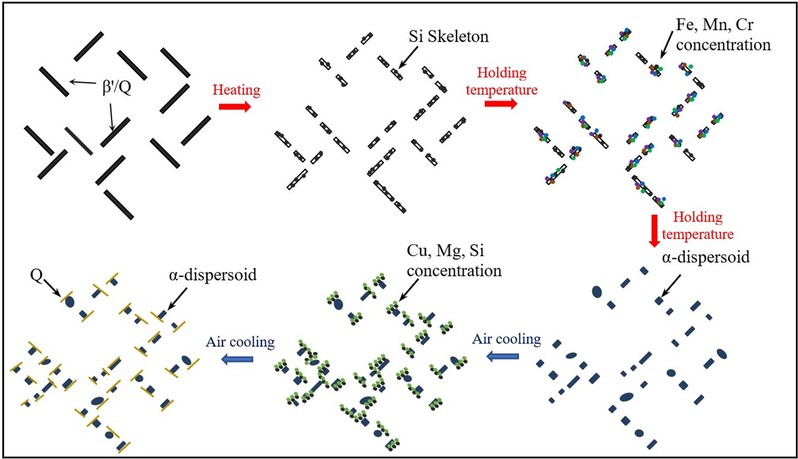

High Fe levels, coarse grains, microstructural inhomogeneities, and coarse dispersoids for recrystallization suppression remain problems for industrial application of Al-Mg-Si (6xxx) alloys. In this study, Al-0.81%Mg-0.81%Si-0.7%Fe alloy billets were fabricated by direct chill (DC) casting at different casting speeds. The results indicate that high-speed (300 mm/min) DC casting can provide fine grains, refined Fe-containing phases, relatively high solid–solute content, and improved distribution of Mn and Cr. After homogenization at 500 °C for 6 h, the α-AlFeMnCrSi dispersoids in the high-speed cast billet decrease in size and increase in number density, compared with the conventional cast billet (100 mm/min). The low homogenization temperature (440 °C) also contributes to the size reduction and increases the number density of dispersoids. Air cooling after homogenization (holding temperature ≥ 500 ℃) results in Q-AlCuMgSi precipitation, which depends on the precipitated substrate of the α-AlFeMnCrSi dispersoids. Moreover, the precipitation processes of α-dispersoids and Q phases are discussed according to TEM and HAADF-STEM results. These results mean that high-speed DC casting can effectively improve the as-cast microstructure by increasing the cooling rate and the as-cast microstructural evolution promotes the precipitation of fine and dense α-dispersoids from the α-Al matrix.

关键词:

Casting, Microstructure, Al-Mg-Si alloy

DOI:10.1002/adem.202000517